Categories

Contact Us

Forging product

Stainless steel forging compared to general forging, has better molding properties. Because stainless steel has good plasticity and ductility, after forging is not easy to break, the shape is not easy to deform.

Category:

Forged Series

Product Details

Advantages of stainless steel forging

Stainless steel is an alloy material with excellent mechanical properties and strong corrosion resistance. In the process of stainless steel forging, the mechanical properties, corrosion resistance, molding properties and mechanical strength of the material can be effectively improved by controlling the forging temperature and forging times and other process parameters. More specifically, stainless steel forging has the following advantages over ordinary forging:

1. Better mechanical properties

After stainless steel forging, the mechanical properties and durability of forgings can be greatly improved. Stainless steel has high hardness and ductility, after forging, can make ordinary stainless steel is not easy to deform or crack in many times of processing, greatly improving the production efficiency and quality of forgings.

2. Higher corrosion resistance

As stainless steel has excellent corrosion resistance, so after forging, its corrosion resistance and corrosion resistance can also be effectively improved. Stainless steel forgings can be adapted to a variety of environments, such as strong acid and alkali environment of chemical equipment, food equipment, marine equipment, and so on.

3. Better molding performance

Stainless steel forging compared to general forging, has better molding properties. Because stainless steel has good plasticity and ductility, after forging is not easy to break, the shape is not easy to deform. Therefore, in the production process, stainless steel forgings can be made into unique shapes and complex structures to meet the needs of different industry sectors.

4. Higher mechanical strength

Stainless steel material can be made through the stainless steel forging process, so that the stainless steel forgings have higher mechanical strength and can withstand higher pressure and gravity. Especially in high temperature and high pressure environment, after forging stainless steel forgings, compared with the traditional ordinary forging materials, more able to maintain stable and safe performance.

SHENDA product specification catalog

| Product name | O.D | THIC | L | |

| Steel pipes | Seamless pipe | φ32mm-φ762mm | 1.6mm-130mm | 6-12.5 |

| LSAW steel pipe | φ406.4mm-φ1422.4mm | 6.4~60mm | 8-12.5 | |

| SSAW steel pipe | φ219mm-φ3500mm | 6nm-25.4mm | 6-12.5 | |

| Heat expanding seamless steel pipe | φ600mm-φ1600mm | 6.35mm-28.58mm | 6-12.5 | |

| Stainless seamless pipe | φ6mm-φ426mm | 1mm-40mm | 6-12.5 | |

| Stainless welded pipe | φ12mm-φ3000mm | 0.5mm-50mm | 6-12.5 | |

| Pipe fittings | elbow | 1/8“-24“(seamless) | 1.6mm-50.01mm | |

| 26“-48"(single welded) | 1.6mm-24.61mm | |||

| 48“-60"(double welded) | 1.6mm-24.61mm | |||

| tee | 1/8“-24“(seamless) | 1.6mm-52.37mm | ||

| 26“-48"(single welded) | 1.6mm-24.61mm | |||

| 48“-60"(double welded) | 1.6mm-24.61mm | |||

| reducer | 1/2"-24" | 1.6mm-50.01mm | ||

| flange | 1/2~-80" | CLASS 150-2500(LB) | ||

| bent tube | 1/2~-48~ | 1.6mm-50.01mm | 22.5deg,30deg,45deg,90deg,180deg,1.0D-10D | |

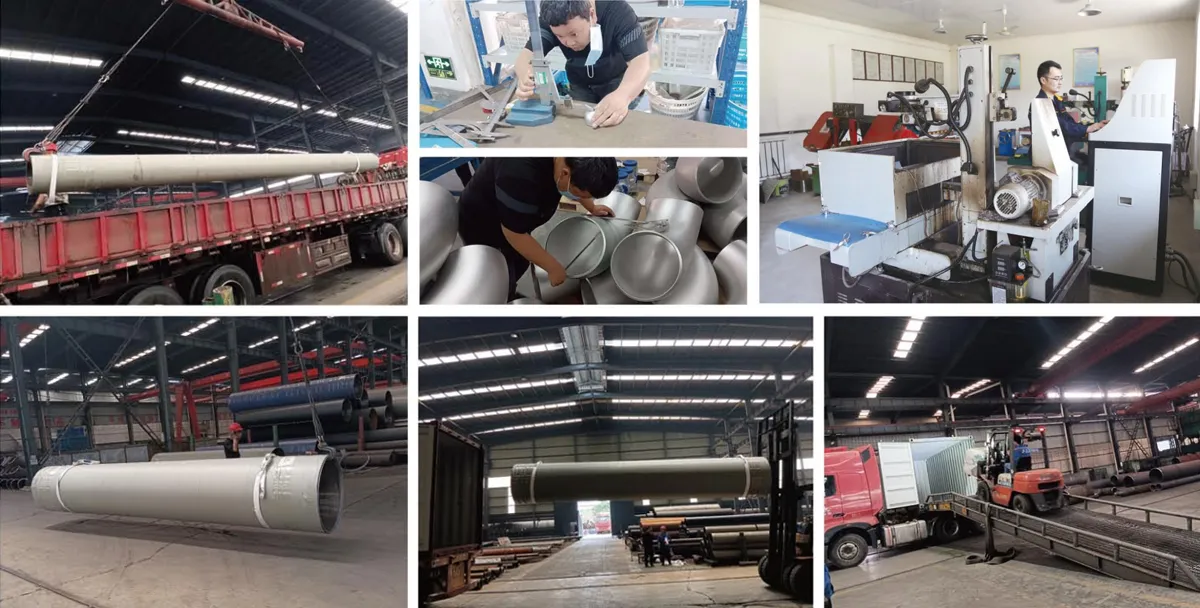

Enterprise Strength

Our main business consists of three divisions: 1. Production and prefabrication of pipe fittings; 2. Production of hot-expanded and cold-drawn steel pipes; 3. Warehousing and sales of alloy steel pipes.4.Warehousing and sales of outsourced products including: stainless steel and carbon steel pipes, fitings, welded pipes, flanges, coupling, oil casing.The main materials of our products are: carbon steel, alloy steel, low temperature alloy steel, pipeline steel, stainless steel, duplex steel, nickel-based alloy steel, copper and copper alloy. We have nine production workshops for cuting, pressing, extrusion, welding, machining prefabrication, pipe rolling, heat treatment, and testing. We have an annual storage capacity of over 30.000 tons of alloy and specialty steel pipes, making us the largest distributor of P91 steel pipes nationwide.

Production Equipment

Our pipe fitting production is equipped with a variety of specialized equipment for cutting,extrusion, pressing,bending, heat treatment, and machining. Currently, we can produce seamless elbows with amaximum size of 1420*80mm, hot-pressed elbows and tees with a maximum size of 1600*200mm, and hot-bending machines for pipes up to 1420*140mm. In particular, we have accumulated extensive production experience in manufacturing pipe fittings with special calibers, wall thicknesses, radii, and dimensions, especially those that are challenging and difficult to produce due to their unique shapes and specifications.With mature technical capabilities, complete molds, and equipment, we have undertaken a large number of non-standard and special-shaped pipe fitting projects. Our prefabrication services for pipeline construction address the low efficiency and high cost associated with on-site welding.These services have been widely acclaimed, providing support for various domestic and international thermal power projects and four major pipeline applications.

Quality Inspection & Shipping

Quality productsand satisfactory service

We adhere to the business philosophy of relying on quality and brand to expand the market and creating value for customers through honesty and trustworthiness.We are dedicated to serving customers both domestically and internationally. We warmly welcome new and old customers to visit us for guidance, and we are eager to sincerely cooperate with you to create a bright future together.

Keywords

FAQs

Our company creates a professional network for sales and services, extends its reach of services over the globe, sets up an integrated system for pre- during and post sale services.

Can you send samples?

Of course, we can provide customers with free samples and express shipping service to all over of the world.

What product information do I need to provide?

Please kindly provide the grade, width, thickness, surface treatment requirement should you have and quantities you need to purchase.

It's my first time to import steel products, can you help me with it?

Sure,we have agent to arrange the shipment, we will do it together with you.

What about product prices information?

Prices various according to periodic price changes of raw materials.

What ports of shipment are there?

Under normal circumstances, we ship from Shanghai, Tianjin, Qingdao, Ningbo ports, you can specify other ports according to your needs.