Categories

Contact Us

Products

hese ingots are then reheated and processed through rolling mills to form billets. However, this process is more time - consuming and less efficient compared to continuous casting.

A steel billet is a semi - finished product of steel. It is usually a long, rectangular - shaped piece of steel that has been cast or continuously cast from molten steel and is further processed to produce various steel products such as bars, rods, and structural shapes.

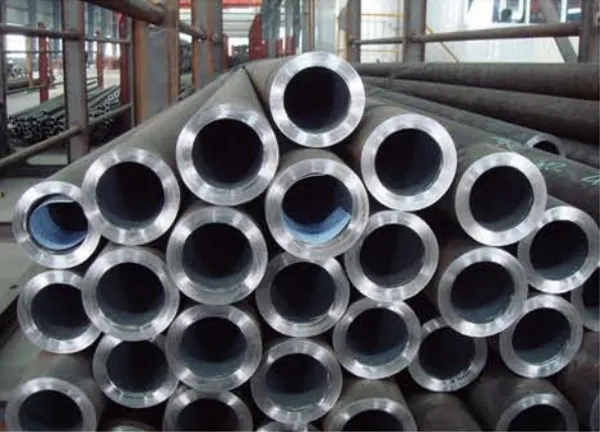

A seamless steel pipe is a tubular product made from a solid round steel billet through a series of processes without a welded seam. It is formed by processes such as hot - extrusion or cold - drawing.

Hot - extrusion: The steel billet is first heated to a high temperature (usually above 1000°C). Then, it is pushed through a die to form a hollow pipe shape.

The tube is drawn through a series of dies to reduce its diameter and wall thickness to the required dimensions. Cold - drawn pipes have better dimensional accuracy and a smoother surface finish.

Carbon steel coil is a kind of iron as the main element, carbon content of less than 2.11%, and contains silicon, manganese, sulfur, phosphorus and other elements of the iron-carbon alloy.

Common specifications and models of carbon steel coils include Q235B, Q345B, S235JR and so on. These specifications of carbon steel coils have different mechanical properties and application scenarios.

The main purpose of alloy steel pipe is used in power plant, nuclear power, high pressure boiler, high temperature superheater and reheater and other high pressure and high temperature pipeline and equipmen

It is used in carbon steel, alloy structural steel and stainless and heat-resistant steel to do the material, hot rolled (extruded, expanded) or cold rolled (drawn) and become.

Alloy pipe has a hollow cross-section, used in large quantities as a pipeline for the transportation of fluids, such as pipelines for the transportation of oil, natural gas, gas, water and certain solid materials.

Compared with solid steel such as round steel, alloy steel pipe is lighter in weight when the bending and torsion strength is the same.

Environmental health: stainless steel pipe is non-toxic and tasteless, will not produce harmful substances, in line with environmental health requirements.

Good compressive properties: stainless steel pipe has high compressive strength, able to withstand high pressure and heavy loads.

High aesthetics: stainless steel pipe surface smooth, uniform color, beautiful installation effect, enhance the overall decoration grade.

Construction field: stainless steel pipe is widely used in building water supply and drainage, heating, air conditioning and other systems.

Special areas: marine engineering, chemical plants, pharmaceutical plants and other areas with special requirements are also often used stainless steel pipe.

Strong corrosion resistance: stainless steel tube has good corrosion resistance, can resist the erosion of various chemicals, prolong the service life.

Environmental health: stainless steel tube is non-toxic and tasteless, will not produce harmful substances, in line with environmental health requirements.

Alloy pipe has a hollow cross-section, used in large quantities as a pipeline for the transportation of fluids, such as pipelines for the transportation of oil, natural gas, gas, water and certain solid materials.

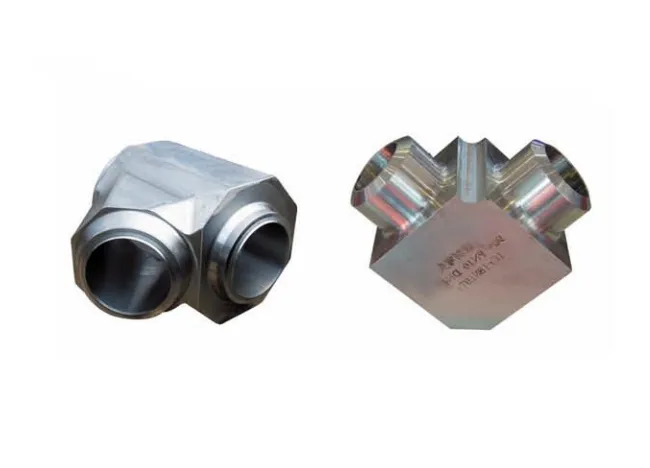

Petrochemical industry: in the field of oil, natural gas and other industries, pipe fittings play an important role in connection, support, fixation, shock absorption, sealing, etc., such as oil and gas pipelines, chemical pipelines, petrochemical pipelines and so on.

Sewage treatment industry: in the field of sewage treatment, pipe fittings are used in environmental protection equipment, such as sewage treatment equipment, sewage treatment pipelines, etc.

Petrochemical industry: in the field of oil, natural gas and other industries, pipe fittings play an important role in connection, support, fixation, shock absorption, sealing, etc., such as oil and gas pipelines, chemical pipelines, petrochemical pipelines and so on.

Sewage treatment industry: in the field of sewage treatment, pipe fittings are used in environmental protection equipment, such as sewage treatment equipment, sewage treatment pipelines, etc.

Sewage treatment industry: in the field of sewage treatment, pipe fittings are used in environmental protection equipment, such as sewage treatment equipment, sewage treatment pipelines, etc.

Petrochemical industry: in the field of oil, natural gas and other industries, pipe fittings play an important role in connection, support, fixation, shock absorption, sealing, etc., such as oil and gas pipelines, chemical pipelines, petrochemical pipelines and so on.

Stainless steel is an alloy material with excellent mechanical properties and strong corrosion resistance.

Stainless steel has high hardness and ductility, after forging, can make ordinary stainless steel is not easy to deform or crack in many times of processing, greatly improving the production efficiency and quality of forgings.

Stainless steel forging compared to general forging, has better molding properties. Because stainless steel has good plasticity and ductility, after forging is not easy to break, the shape is not easy to deform.

The main materials of stainless steel flanges include carbon steel, low alloy steel and stainless steel.

Stainless steel flanges can be categorized into types such as 304 and 304L depending on the material.